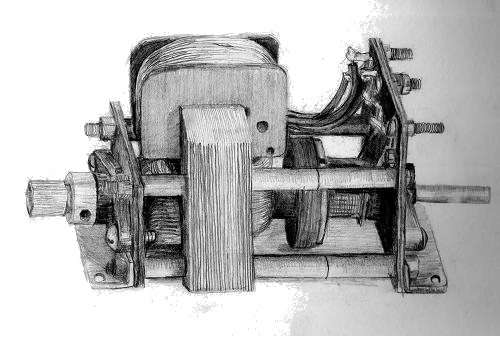

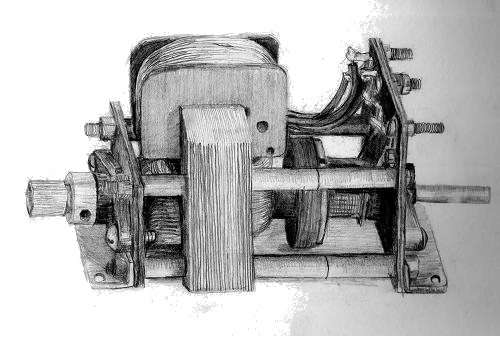

Taycol Model Marine Electric Motors

When a new Taycol is running without load, there should be no more noise than a low hum. However, when a typical old Taycol is run today, there is often a buzzing noise, or a rattle. This is a sign that the bearings have widened due to wear.

To talk about a Taycol havig bearings is rather a misnomer. They have no specialised bearings, and the shaft simply runs in the holes in the Paxolin end-plates. 1/16" thick, They do the job surprisingly well for a long time, but eventually they wear out.

One good feature of Taycol design is that they are built from simple stock component parts, so there is little that cannot easily be re-manufactured. 1/16" paxolin is easy to obtain and cut, and the patterns for the end plates are here - though you can easily take the dimensions off your old one,ad are recommeded to do so!

.

.

If you are looking for a cheaper and easier way to minimise the buzzing sound of wear, you will find that the larger Taycols have multiple layers of Paxolin, giving a larger bearing surface. The Supermarine, for instance, has three layers, giving a 3/16" thick bearing.

If you loosen the screws holding these layers in position, and gently shift each layer in a different direction, you will be able to artificially lower the clearances around the shaft, and the motor will then (for a short time) run more smoothly. Of course, this will not last for a long time - the shaft is now supported on only one Paxolin layer and will wear through that more rapidly. It will, however, give you an idea of how a new Taycol should sound!

The state of wear of the Paolin bearings can be easily ascertained by holding the motor and trying to move the shaft up and down. On a new Taycol there should be no noticable movement at all. On a typical old motor, you will hear a slight click and feel a small movement as the shaft shifts in the bearing.

If you are making new end-plates,there are some cutting lines below. The shaft holes should be an interference fit. They will soon wear a suitable clearance. To this end it is a good idea to emery off any major rust there may be on the shaft before pushing it through the new Paxolin end-plates, so that the holes are not widened too much.

Small ballraces exist for all the Taycol shaft sizes, and it is a compatratively simple procedure to widen an end-plate to take a whole ball-race, add an extra end-plate to hold it in place, and have a Taycol with ball-bearngs. Though that would perhaps be guildng the lilly....

Taycol Oddities - a series of musings on various Taycol-related matters or features of the Taycol motors which I don't understand.

Taycol Bearings

Large Motor Cutting lines - Front

1/16" Paxolin

Large Motor Cutting lines - Rear

1/16" Paxolin

Bearing Reinforcement

1/16" Paxolin

Small Motor end-plates

1/16" Paxolin