Cleaning and Refurbishing...

Taycol Oddities - a series of musings on various Taycol-related matters or features of the Taycol motors which I don't understand.

What I do when I get a Taycol?

Well, I suppose it depends what I want it for. A good collector's item should not normally be touched. But usually they are in quite a mess, and would benefit from a clean.

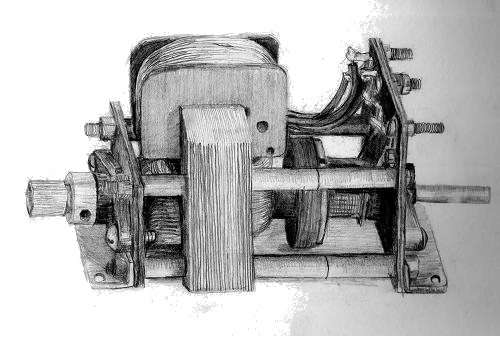

I start by giving them a generous squirt of WD40. This is because I am going to wash them with water, and I'd like the little crevices to be oil rather than water filled. Turning the shaft will give a feel for the state of the brushgear, and waggling the shaft up and downwill tell you how worn the shaft bearings are. In a new Taycol no movement should be detected, but most Taycols around today have quite a bit of slop. Then I will usually disassemble them into two main parts - the armature and the field coil. There is no need to unsolder anything, but it is a good idea to use a very thin box spanner for all the nuts, to avoid adding scratches.

A quick examination of the brush gear will tell us something about the use the motor has had. Most motors will have been run without oiling the brushgear at some time - this wears the surfaces quite badly. In some cases I may need to make replacements or improve the shape and tension of the springs, but this can wait until after I have covered the parts with washing-up liquid, toothbrushed it firmly in and then washed under a hot tap. Rinse and repeat - then dry and bring the parts up to a warm/hot temperature with a hairdryer.

Once very dry a brass wirebrush is used on any rust, and the separate brass spacers and feet are polished with brasso.

At this point I check electrical continuity. The two field coils are easy to check, and each pair of contacts on the commutator should give a similar reading. Remember to check that there is NO link from any of the wiring to the field coil or armature laminations! I have one motor with a short between a coil and the chassis - it will run fine but you are not advised to touch it while it is doing so - induced voltages of 50-100v give a bit of a jolt!

The motor is reassembled, with new or adjusted brushes as necessary and given another WD40 spray. If the paxolin bearings were poor I will usually cut another plate, using the old one as a guide, to ensure smooth running. Finally, a generous dollop of engine oil is applied to the paxolin/shaft joint and the brushgear. And then it is ready to start...

The following advice was provided to a reader who had obtained a Supermarine which didn't seem to work, and wanted to refurbish it. A picture soon showed that the jumper links were missing, but I though that the general refurbishment advice I wrote could do with a wider circulation. So here it is. Any comments/additions gratefully accepted, as always....

" Ah, yes - I think I see your problem. Your Supermarine is missing the two jumper links which connect the lower leads from each coil to the brushes, and has some capacitors attached somewhere. It has probably been rewired to operate in a radio controlled boat. Once this is corrected I am sure that it will run very well....

Taycols do not have capacitors as standard, but many people will have attached them for spark suppression when using the motor in an R/C boat. The common Supermarine does not come with the extra reversing coil, and to enable reverse people removed the links and used a double-pole changeover switch, as shown here: Reversing page

The capacitors which are connected can be discarded (they are the wrong type for spark suppression anyway) and the jumper links should be quite easy to make from a piece of 35thou/1mm brass - they are simply a strip 20.7mm long by 8.44mm wide, with a 3.6mm slot cut in it lengthways, as shown in the reference. That picture shows you the general shape, or I can draw a sketch for you if you want. Get the motor running properly first, then if you need suppression follow the suppression advice on the Taycol site.

The link I have provided should give you the general circuit diagram. It's all quite simple - this is 50 year old technology! The motor should be quite easy to disassemble - most of it can be cleaned with dish-washer solution, though it's usually a good idea to keep armatures fairly dry, or to dry them thoroughly if they get wet. The brass spacers and feet will polish up nicely, and a wire brush will remove any rust from the iron coil holder. Thread the spacers onto their central rod, place in a drill, and spin them against a rag with brass polish – that will soon have them shining with little effort.

I would expect to see a coil resistance for the Supermarine of about 6 ohm, and a resistance between two adjoining commutator plates of about 8 ohm. Check specifically to see that there is no path between either of the coil contacts and the iron laminations - if there is that indicates a short to the chassis. The motor will often run fine like this, but will tend to give unpleasant shocks if handled - there is a lot of induction going on in these beasts!

On the mechanical side there are two places to worry about wear - the brushes and the bearings. The bearings are simply a steel shaft running in 1.8mm paxolin/tufnol - two pieces in the case of the Supermarine. You should try to move the shaft up and down by hand while it is still assembled - there should be no detectable vertical movement. If there is, the bearings are worn, and you will probably find that the motor vibrates quite a lot when running, and makes a distinctive 'buzz' sound. When running with good bearings these motors should just hum. A temporary cure can sometimes be affected by loosening the two paxolin plates and sliding them relative to each other to minimise the shaft clearance - but it's better to cut and drill a new pair of plates out of readily available paxolin or tufnol.

The brushes are probably best replaced - they look as if the central hole that the positioning pin locates into is worn, and the bushes are lying at an angle. For 50-year old motors there is no readily available spares outlet, but again these can be made easily - see here: Brush Repair This shows a 'Double Special', but the brushes are exactly the same. Brush pressure adjustment is probably done by adjusting for maximum revs - I find that my brushes have a spring force of about 50-100 gm. Taycol recommend running the motors on 2 volts – if everything is properly adjusted the motor should turn slowly...

Do NOT forget to lubricate the brushes before running the motor! This requirement is a feature of Taycol motors, with their copper/brass brushgear. I know that almost all other motors using carbon/graphite brushes require the brushgear to be kept completely free of oil, but Taycols are different! See here: Lubrication I believe that ignoring this lubrication requirement results in increased brush wear, sparking, and the reputation that Taycols had of being impossible to suppress...

I hope this helps - do ask again if anything is not clear...."