Some interesting amateur modifications...

Taycol Model Marine Electric Motors

Taycol Oddities - a series of musings on various Taycol-related matters or features of the Taycol motors which I don't understand.

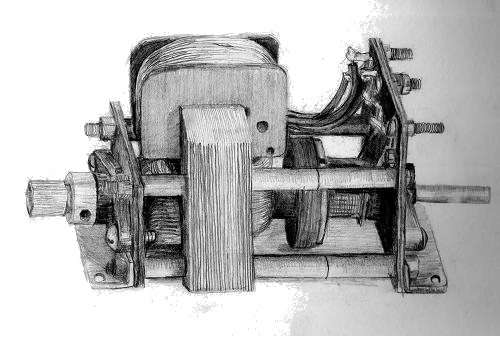

The first one has a non-standard commutator - presumably made when the original broke. If the brushes wear down to breaking point they can dig right into the thin copper/paxolin commutator and split it.

Here a commutator has been made out of a piece of PCB (probably fibreglass) in the style of the larger Taycols. A big brass plate has been cut in three segments and pinned/glued on. The brushes are particularly interesting - brass spring with a scrap of copper wire threaded through them at the end. This produces a good thin contact, wears well, and should be easy to replace.

Occasionally I find a Taycol going cheaply on ebay or elsewhere and purchase it to refurbish. And in some cases I find that rather difficult!

Here are a couple of Meteors I obtained recently, with distinctly non-standard mods. I thought you might be interested...

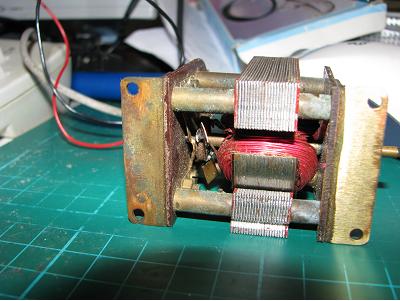

Here is a fairly typical old Meteor in reasonable condition. The nuts will all be replaced with new ones, but apart from that it doesn't need much attention. Notice the suppression - a huge capacitor, far in excess of what is needed. This will simply lower the motor performance. And it's connected across the input leads - a common error. Motors need capacitors connected across the brushes - which, for field-wound Taycols, are NOT the input leads...

Let's look at the underside of the motor above. What are those little squares soldered onto the commutator? That's right - someone has decided that the motor needs a fan, and has created a (very inefficient) one. Open frame motors rarely need directed ventilation, and I wonder what the centrifugal force is doing to the solder joints...!