There is one obvious way to completely avoid Taycol motor interference to the radio which is controlling it - use a modern 2.4 Ghz system. Any RF radiation from a Taycol is invariably at a far lower frequency, and even a cheap 2.4 Ghz will function with no disturbance whatsoever next to an completely unsuppressed motor.

However, note that RF interference carried through power leads may still disturb components like an ESC, and other nearby operators may be using lower frequency systems which are more prone to interference, so proper suppression should always be employed to avoid causing unwanted RF radiation.

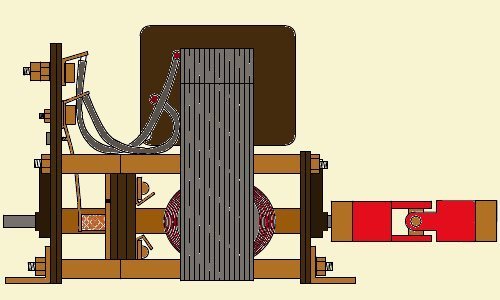

Suppression is fairly straightforward - a 0.1μfd capacitor between the brushes, and a 0.1μfd capacitor from each brush to the frame. If there is still a problem, earth the motor frame and wrap the brush power lines around a ferrite ring.

If you want to know more about interference, here is a rather more comprehensive

discussion of the subject...

Any Taycol you obtain, over 60 years since they were made, is likely to be fairly worn. Those that are still boxed and in mint condition are probably collectors items - not to be sullied by actual use! And of course there are no spare parts to be found since the factory ceased production.

However, Taycols had very few parts which were made using complex tooling. All the basic parts are easily created from stock materials. In particular, the brushes and bearings - the two parts which wear, were made from spring copper sheet and paxolin sheet respectively - with the Large motors using woven copper mesh. All these items are readiy accessible - you just have to know what shape to cut them into.

This data is available here at the

Bearings Page,

Brushes Page 1 and

Brushes Page 2

Since you can keep making the parts of a Taycol which wear out, there is no reason why these motors should not be used continually, into the far future...!

One reason that the Taycols have a reputation for being difficult to suppress is that, unusually, they require their brushgear to be regularly lubricated. That is what the small holes in the paxolin plates over the commutators are for!

Normal motor brushes must NEVER be oiled. Bit if Taycol brushes are not kept well oiled they will wear and start to spark badly. The result is often that old Taycols have a major problem with interference, which can be minimised with a few drops of oil onto the brushgear and commutator.